Cerec

In the era of technological innovations, dentistry is one of the leading medical branches that is affected by a modern technological improvement. The main aim of these changes is to develop new, more durable, resistant, more natural and faster ways of creating healthy smiles.

What is Cerec?

There are many dental restorations that usually needs to reestablish the physiological function of the oral cavity and additional to improve patients’ esthetic appearance. Depending on the extent of dental rehabilitation, there is a wide range of possible therapeutic solutions, from small defects of cavity preparation to full dental arch reconstructions. Besides conventional cavity preparation of caries lesion, with the placement of composite fillings, there are many other options for even these simple procedures.

CEREC is dental systems produced by Sirona (former Siemens) company. CEREC is the abbreviation for Chairside Economical Restoration of Esthetic Ceramics that is based on CAD/CAM (computer aided design/computer aided manufacturing) in order to produce dental restoration in single-visit.

The greatest advantage of this system is the greater comfort for the patients since the entire prosthodontic treatment can be performed within one appointment. Whether you need veneers, single crowns, onlays, inlays or overlays, or you have more extensive prosthodontic treatment, everything can be finished during one visit to your dentist with time for a coffee break.

Scan And Analysis

After detail examination and analysis, when you and your dentist define the best prosthodontic solution for your individual case the in-office procedure for your prosthodontic restoration starts with making a digital impression of your teeth and jaws. Cerec Omnicam is an elegant solution for taking a digital impression without discomfort that is present during the conventional method with impression tray and powder.

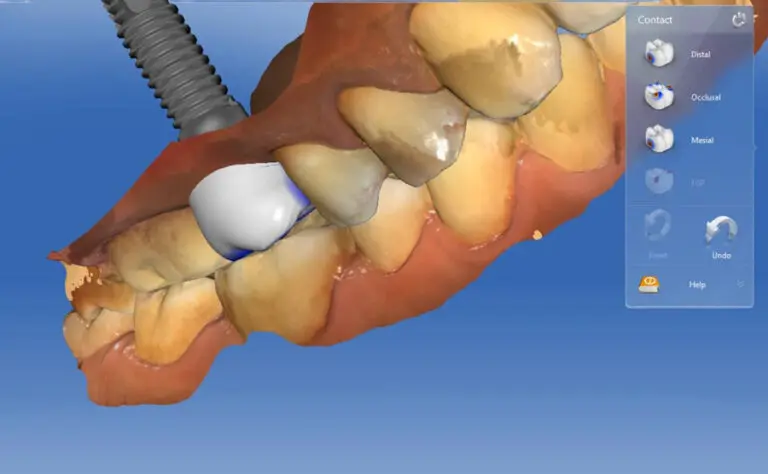

This scanner allows placing the patient in any position during the procedure while scanning the entire dental arch with the highest precision. This provides more comfort for the patients so as for the dentist and reduces the time needed for impression taking. Beside this, another advantage of Omnicam is the possibility of color determination. Digital color determination has a great impact of the final restoration look and patient’s satisfaction since sometimes it’s difficult to determine the proper tooth shade. Usually, teeth have more than one shade in different anatomic areas of the tooth crown. After the scanning is finished, digital impressions may be electronically forwarded for the analyzation by CEREC Software. The Software provides the precise design of your future restoration so that it perfectly fits with the rest of your teeth by shape, color, and size without affecting your natural occlusal balance.

Production Of Future Restoration

After scanning and analysis are completed you can have a coffee break for 15 minutes while waiting for your restoration to be finished. CEREC Milling and Grinding units will fabricate the restoration with the precision of 25 micrometers.

Since the Milling and Grinding units can be synchronized with CEREC Software it is possible to send scans to the laboratory or produce complete prosthodontics in the dental office. Each type of restorations can be easily fabricated. From inlays, overlays, single crowns, bridges, abutments or surgical guides. There is a wide range of materials that can be used for CEREC fabrication, such as plastic, ceramic or metal. One of the main advantages of the entire CEREC system is the possibility of creating final restoration from almost any material, from zirconia dioxide to feldspar ceramics so as sintered metal Co Cr alloy.

CEREC’s zirconia blocks come in different sizes and shades, which makes it ideal for all types of crowns and bridges. Beside this, CEREC produces a special block for screw-retained crowns for implants so as the other type of blocks designed for custom-made meso abutments. CEREC’s feldspar ceramics are specially designed for veneers, partial crowns or inlays. With this C blocks, CEREC has stepped out among other materials with its C PC and C In blocks. C PC blocks are intended for natural-looking anterior and posterior crowns since it has three different color layers, based on chroma which allows simple design and individual determination of color gradient for each patient and each crown. On the other hand, blocks C In are made with inner, highly chromatic dentin-like layer covered with a translucent enamel-like layer. Based on specific individual requirements, the software can calculate which portion of the block should be grided for the most natural look of the future crown. Considering these advantages, C In blocs are perfect for anterior restoration with highest esthetical properties.

When talking about materials and CEREC systems, it is important to emphasize another huge advantage. Previously mentioned blocks are produced by Dentsply Sirona so as CEREC system, but it is compatible with materials from other companies such as VITA-Zahnfabrik, Ivoclar Vivadent, Merz Dental, 3M ESPE, GC, COLTENE, Shofu and Kuraray Noritake. This allows patients to choose the best restoration based on their individual needs and capabilities.

Sintering And Glazing- A Final Step In Restoration Production

When production of restoration is finished in Milling and Grinding unit, the restoration can be placed in the patient’s mouth for a final evaluation before cementation. This restoration needs to undergo another, final step in the restoration production process called sintering and glazing. Sintering is a process that takes place in a specially designed furnace that heats up the restoration up to the temperature below melting which gives the restorations its final properties such as hardness, strength and temperature conductivity.

CEREC SpeedFire furnace is the smallest and the fastest furnace on the market with a quite short period of 10-15 minutes for sintering and glazing. Beside this, SpeedFire is ideal for all CEREC block but it is also compatible with IPS.emax CAD (by Ivoclar Vivadent) and VITA Suprinity (by VITA Zahnfabrik). After this, final, step in production, the restoration is ready for cementation and the patient can leave the dental office with permanent prosthodontics.

Considering all previously named advantages of CEREC system it becomes clear that this system is the most comfortable option in the dental industry, both for the patients and the dentists. It cuts off the time for productions with the minimal chance for restoration’s inaccuracy that is often present during the conventional procedure in restoration production with traditional impressions and laboratory procedures. Impressions are replaced with more comfortable scans, the design is more precise thanks to the software’s algorithm, a wide range of materials can be used and a wide range of indications can be covered. As a most valuable advantage, the patient can finish the entire process in single-visit at their dentist in just a few hours. Considering that time is money, this is the cheapest and at the same time most valuable dental intervention.